Get to know the MQ2 / MQ-2 Sensor

MQ2 is a sensor module that can be used to detect flammable fumes or gases at concentrations between 200 ppm – 10,000 ppm. What is ppm? ppm stands for “part per million”, which is a unit that states the amount or concentration of substances in every 1 million. Almost the same as the unit of percent (%) which means “per cent”. Usually ppm is used to measure the concentration of substances in a liquid or air / gas. 1 ppm is equivalent to 1 mg / L or 1 mg / Kg.

Gases that can be detected by MQ2 include LPG, Hydrogen (H2), Methane (CH4), Carbon Monoxide (CO), Alcohol, Smoke (Smoke) and Propane. This sensor is designed for indoor use at room temperature. Usually applied to the combustible gas leak detection equipment in a house, agency, warehouse or industrial factory.

In the previous article, that is :

Example of the MQ2 MQ-2 Smoke / Gas Sensor Program with Arduino

using only the MQ2 sensor module to detect / create gas alarms that are detected at a certain level, the following article will present an example of a more detailed MQ2 program that measures the concentration of each gas detected according to the datasheet of the MQ2 sensor.

How MQ2 / MQ-2 works

MQ2 or MQ-2 is a Metal Oxide Semiconductor (MOS) type gas sensor or also known as Chemiresistors because the detection is based on changing the resistance value of the material / material from the sensor when the material / material is in contact with the gas detected.

By using a voltage divider circuit construction, the content of a gas can be measured / obtained. The resistance value of the MQ2 sensor is directly proportional to the level or concentration of a gas detected.

Because it is made or arranged into a voltage divider circuit, the voltage value of the sensor will automatically follow or be proportional to the value of the resistance. Well, from this voltage value that can then be read with a microcontroller like Arduino, STM32, NodeMCU ESP8266 or Raspberry Pi.

Specification

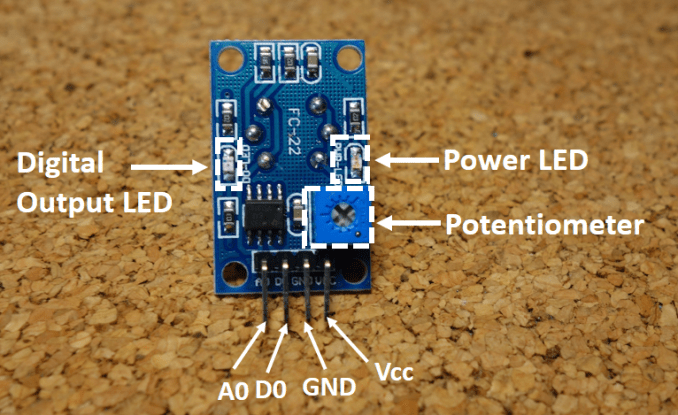

- Power indikator LED

- TTL sinyal output LED

- Digital output DO

- Analog output AO

- TTL output (DO) aktif Low

- Semakin banyak onsentrasi gas terdeteksi maka tegangan AO semakin tinggi

- dimensi : 32 (L) * 20 (W) * 22 (H)

- Input voltage : DC5V

- Power consumption ( current ) : 150mA

- DO output : TTL digital 0 and 1 (0.1 and 5V)

- AO output : 0.1 – 4 V

Hardware Required

- Arduino Uno / Arduino Nano / Arduino Pro Mini

- MQ2 Sensor Modul

- Some Dupont M-F or F-F jumper cables

Circuit / Wiring Diagram

| MQ2 | Arduino |

| 5V | 5V |

| GND | GND |

| A0 | A0 |

MQ2 calibration

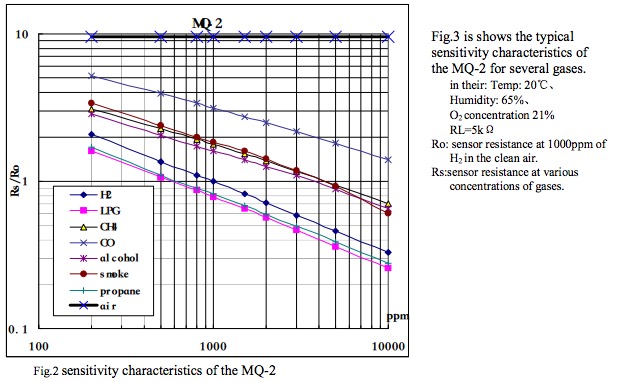

To be able to measure the concentration of the gas detected by the MQ2 sensor, we must calibrate based on the MQ2 datasheet in the form of a straight line curve of the sensitivity of MQ2 to some of the gases detected as shown below :

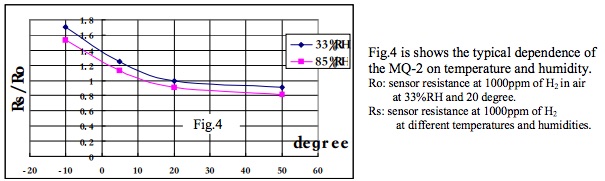

The second curve shows the characteristics of the MQ2 sensor on temperature and humidity.

Program Code

Copy the following program, then upload it to the Arduino board and we must first do it in a clean air condition for calibration so that the Ro value from the sensor can be obtained. The Ro value obtained can then be used in measuring the concentration of gas detected in the air.

/*******************Demo for MQ-2 Gas Sensor Module V1.0*****************************

Support: Tiequan Shao: support[at]sandboxelectronics.com

Lisence: Attribution-NonCommercial-ShareAlike 3.0 Unported (CC BY-NC-SA 3.0)

Note: This piece of source code is supposed to be used as a demostration ONLY. More

sophisticated calibration is required for industrial field application.

Sandbox Electronics 2011-04-25

************************************************************************************/

/************************Hardware Related Macros************************************/

#define MQ_PIN (0) //define which analog input channel you are going to use

#define RL_VALUE (5) //define the load resistance on the board, in kilo ohms

#define RO_CLEAN_AIR_FACTOR (9.83) //RO_CLEAR_AIR_FACTOR=(Sensor resistance in clean air)/RO,

//which is derived from the chart in datasheet

/***********************Software Related Macros************************************/

#define CALIBARAION_SAMPLE_TIMES (50) //define how many samples you are going to take in the calibration phase

#define CALIBRATION_SAMPLE_INTERVAL (500) //define the time interal(in milisecond) between each samples in the

//cablibration phase

#define READ_SAMPLE_INTERVAL (50) //define how many samples you are going to take in normal operation

#define READ_SAMPLE_TIMES (5) //define the time interal(in milisecond) between each samples in

//normal operation

/**********************Application Related Macros**********************************/

#define GAS_LPG (0)

#define GAS_CO (1)

#define GAS_SMOKE (2)

/*****************************Globals***********************************************/

float LPGCurve[3] = {2.3,0.21,-0.47}; //two points are taken from the curve.

//with these two points, a line is formed which is "approximately equivalent"

//to the original curve.

//data format:{ x, y, slope}; point1: (lg200, 0.21), point2: (lg10000, -0.59)

float COCurve[3] = {2.3,0.72,-0.34}; //two points are taken from the curve.

//with these two points, a line is formed which is "approximately equivalent"

//to the original curve.

//data format:{ x, y, slope}; point1: (lg200, 0.72), point2: (lg10000, 0.15)

float SmokeCurve[3] ={2.3,0.53,-0.44}; //two points are taken from the curve.

//with these two points, a line is formed which is "approximately equivalent"

//to the original curve.

//data format:{ x, y, slope}; point1: (lg200, 0.53), point2: (lg10000, -0.22)

float Ro = 10; //Ro is initialized to 10 kilo ohms

void setup()

{

Serial.begin(9600); //UART setup, baudrate = 9600bps

Serial.print("Calibrating...\n");

Ro = MQCalibration(MQ_PIN); //Calibrating the sensor. Please make sure the sensor is in clean air

//when you perform the calibration

Serial.print("Calibration is done...\n");

Serial.print("Ro=");

Serial.print(Ro);

Serial.print("kohm");

Serial.print("\n");

}

void loop()

{

Serial.print("LPG:");

Serial.print(MQGetGasPercentage(MQRead(MQ_PIN)/Ro,GAS_LPG) );

Serial.print( "ppm" );

Serial.print(" ");

Serial.print("CO:");

Serial.print(MQGetGasPercentage(MQRead(MQ_PIN)/Ro,GAS_CO) );

Serial.print( "ppm" );

Serial.print(" ");

Serial.print("SMOKE:");

Serial.print(MQGetGasPercentage(MQRead(MQ_PIN)/Ro,GAS_SMOKE) );

Serial.print( "ppm" );

Serial.print("\n");

delay(200);

}

/****************** MQResistanceCalculation ****************************************

Input: raw_adc - raw value read from adc, which represents the voltage

Output: the calculated sensor resistance

Remarks: The sensor and the load resistor forms a voltage divider. Given the voltage

across the load resistor and its resistance, the resistance of the sensor

could be derived.

************************************************************************************/

float MQResistanceCalculation(int raw_adc)

{

return ( ((float)RL_VALUE*(1023-raw_adc)/raw_adc));

}

/***************************** MQCalibration ****************************************

Input: mq_pin - analog channel

Output: Ro of the sensor

Remarks: This function assumes that the sensor is in clean air. It use

MQResistanceCalculation to calculates the sensor resistance in clean air

and then divides it with RO_CLEAN_AIR_FACTOR. RO_CLEAN_AIR_FACTOR is about

10, which differs slightly between different sensors.

************************************************************************************/

float MQCalibration(int mq_pin)

{

int i;

float val=0;

for (i=0;i<CALIBARAION_SAMPLE_TIMES;i++) { //take multiple samples

val += MQResistanceCalculation(analogRead(mq_pin));

delay(CALIBRATION_SAMPLE_INTERVAL);

}

val = val/CALIBARAION_SAMPLE_TIMES; //calculate the average value

val = val/RO_CLEAN_AIR_FACTOR; //divided by RO_CLEAN_AIR_FACTOR yields the Ro

//according to the chart in the datasheet

return val;

}

/***************************** MQRead *********************************************

Input: mq_pin - analog channel

Output: Rs of the sensor

Remarks: This function use MQResistanceCalculation to caculate the sensor resistenc (Rs).

The Rs changes as the sensor is in the different consentration of the target

gas. The sample times and the time interval between samples could be configured

by changing the definition of the macros.

************************************************************************************/

float MQRead(int mq_pin)

{

int i;

float rs=0;

for (i=0;i<READ_SAMPLE_TIMES;i++) {

rs += MQResistanceCalculation(analogRead(mq_pin));

delay(READ_SAMPLE_INTERVAL);

}

rs = rs/READ_SAMPLE_TIMES;

return rs;

}

/***************************** MQGetGasPercentage **********************************

Input: rs_ro_ratio - Rs divided by Ro

gas_id - target gas type

Output: ppm of the target gas

Remarks: This function passes different curves to the MQGetPercentage function which

calculates the ppm (parts per million) of the target gas.

************************************************************************************/

int MQGetGasPercentage(float rs_ro_ratio, int gas_id)

{

if ( gas_id == GAS_LPG ) {

return MQGetPercentage(rs_ro_ratio,LPGCurve);

} else if ( gas_id == GAS_CO ) {

return MQGetPercentage(rs_ro_ratio,COCurve);

} else if ( gas_id == GAS_SMOKE ) {

return MQGetPercentage(rs_ro_ratio,SmokeCurve);

}

return 0;

}

/***************************** MQGetPercentage **********************************

Input: rs_ro_ratio - Rs divided by Ro

pcurve - pointer to the curve of the target gas

Output: ppm of the target gas

Remarks: By using the slope and a point of the line. The x(logarithmic value of ppm)

of the line could be derived if y(rs_ro_ratio) is provided. As it is a

logarithmic coordinate, power of 10 is used to convert the result to non-logarithmic

value.

************************************************************************************/

int MQGetPercentage(float rs_ro_ratio, float *pcurve)

{

return (pow(10,( ((log(rs_ro_ratio)-pcurve[1])/pcurve[2]) + pcurve[0])));

}

After the program or sketch has been uploaded successfully, observe the results by opening the Serial Monitor at baudrate : 9600 bps.

Thus the tutorial is more detailed or deeper than the use of MQ2 sensors to measure the content or concentration of gases : LPG, Hydrogen (H2), Methane (CH4), Carbon Monoxide (CO), Alcohol, Smoke (Asap) dan Propane in the air.

+++++ May be Useful +++++

Leave a Reply